A range of linear piston and stepping type actuators are available. Controls with all common protocols are offered.

A range of linear piston and stepping type actuators are available. Controls with all common protocols are offered.

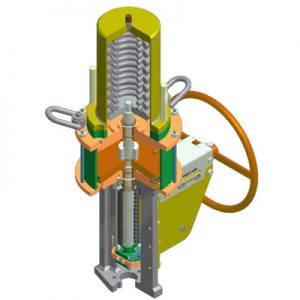

The N-Line Valves model P actuator is a pneumatically powered (produced gas or instrument air) linear output actuator. The actuator is offered in 3 primary models of Fail Open, Fail Close and Fail Last Position, with optional side mount manual override. Standard all steel construction with optional stainless steel construction makes this an ideal actuation for heavy salt spray offshore environments.

The optional external spring cartridge offers a safety advantage in any maintenance situation and allows the actuator to be powered with sour gas and other corrosive media. Piston seal is a superior quad seal to prevent hysteresis and the piston contains a wear ring /bushing for long service life. All internal components are plated, the cylinder is hard chromed and honed and the traveling stems are stainless steel. Spring assemblies and housings are coated for corrosion resistance.

Adjustable travel stops are available to limit travel. Actuators are available with a full range of accessories and controllers / positioners. Options also include gages, filter regulators, solenoid valves and bypass systems. Units can be custom tailored to specific applications on request

Angle Mount actuator allows for trim change or service without actuator removal from the choke and no recalibration requirements, disconnecting lines or electrical connections.

The N-Line Valves SA-II Stepping Actuator is a pneumatically or hydraulically powered rotary indexing output actuator. The actuator consists of two power cylinder and pawl assemblies, from which the drive wheel and output shaft are driven.

One operating cycle consists first of pressurizing one cylinder thereby extending the pawl to engage the drive wheel and thus incrementally rotate the output shaft in the appropriate direction, the cylinder is then depressurized retracting the pawl to its rest position. This single operating cycle rotates the output shaft of the actuator and correspondingly the valve stem by 30°. This operating cycle is repeated until the valve reaches the desired position.

To drive the actuator and the valve in the opposite direction, an operating cycle is repeated using the other cylinder.

When the cylinders are depressurized, the pawls are disengaged from the drive wheel, allowing the drive wheel to be rotated manually through the manual override on the outside of the actuator to position the valve. A spring detent prevents position drift from vibration. Local visual position indication is via a stainless steel micrometer for unequaled accuracy and reliability. A housing containing limit switches, a position transmitter and terminal strip is mounted externally on the yoke for direct valve stem position feedback via 4-20mA signal including HART or digital protocols. All recognized standards for electrical apparatus are available.

The housing is a fully sealed steel housing treated for corrosion resistance and long service life in severe environments.

The SA-II Stepping Actuator is designed to allow in-field retrofit onto existing valves without the requirement to dismantle pressure-containing components

N-line use electric actuators from third party manufacturers. This include Rotork, Emerson and others.