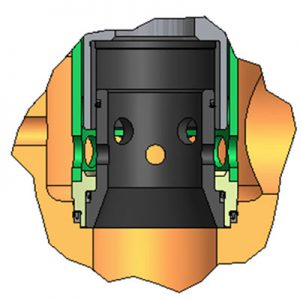

The External Sleeve type trim uses a flow sleeve moving over the outside of a ported cage to control flow. A metal to metal seat design on the outside of the flow sleeve, out of the high velocity flow areas assures positive shut off and an extended seat life.

The External Sleeve type trim uses a flow sleeve moving over the outside of a ported cage to control flow. A metal to metal seat design on the outside of the flow sleeve, out of the high velocity flow areas assures positive shut off and an extended seat life.

High erosion resistance of this trim design leads to its use in severe service that may include high pressure drops and fluids with entrained solids such as formation sands. This trim is furnished in a proprietary blend of Solid Tungsten Carbide with an Equal Percentage characteristic.

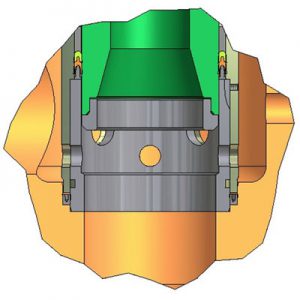

The Plug and Cage trim type is proven for its effectiveness in high flow liquid and multi phase flow.

In the closed position, the plug makes contact with a prepared shoulder in the cage to facilitate positive shut off.

For Class V and VI an additional non elastomeric seal is used in the low flow area of the seat for repetitive positive shut off.

This trim is available with Linear Characteristic or Equal Percent in surface hardened Stainless Steel or Solid Tungsten Carbide for erosive service. An optional full carbide plug can be used for extreme solids production.

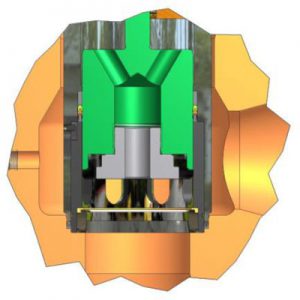

This version of Plug and Cage trim design gives the maximum flow capacity for a cage trim choke valve. This is especially useful in low pressure drop applications and end of life wells.

This version of Plug and Cage trim design gives the maximum flow capacity for a cage trim choke valve. This is especially useful in low pressure drop applications and end of life wells.

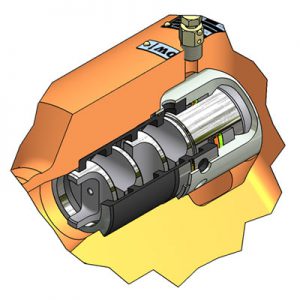

The N-Trim SPMS or LMS is a severe service trim solution to reduce noise, prevent cavitation and with the correct material selection, resist erosion.

The trim consists of a single path multi stage plug and corresponding seats with the appropriate number of stages to prevent cavitation. Several mechanisms are utilized in the design to assist with the conversion of energy without problems of incipient cavitation in liquids.

The N-Trim SP is typically applied in extreme pressure drop valves in water injection applications.

The N-Trim MPMS is a severe service trim solution to reduce velocity, noise and with the correct material selection, resist erosion. The trim consists of a multi path, multi stage cage with the appropriate number of stages to remove the energy through a tortuous path. Several mechanisms are utilized in the design to assist with the conversion of energy during the pressure step down process.

The N-Trim MPMS is typically applied in extreme pressure drop valves for gas and liquid applications